After developing the Nano Simon I decided to see what other Simon projects were around. I found this very interesting project by David johnson-Davies. He has loads of interesting info and projects on his Technoblogy website. I had never done bare chip coding before but by following his beginners tutorial I was able to start working with ATtiny85s in no time. While using the ATtiny85 does not offer much savings over the Nano clones I used in my previous Simon project, the fact that they can be powered by a coin cell and use next to no power when in sleep mode made this a project to pursue. I decided to take his excellent code and schematics and create my own version of his project. I chose a round design and added a hole so it could hang from a lanyard. I also got some self-adhesive felt circles to stick on the back to protect from the sharp bits.

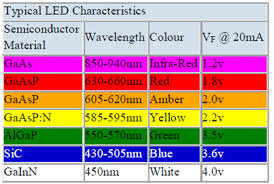

I decided to choose the unusual LED colors because of the voltage drop. I thought green and blue LEDs might have a too large of a drop and not work for the 3v operating voltage. Then again they might be fine.

I programmed the ATtiny85 chips with with a slightly modified version of David's code using the Tiny AVR Programmer from Sparkfun. The CC-BY 4.0 schematics and board info can be found on the EasyEDA project page. The cost of boards, parts, lanyard, felt and shipping was $65 for 10 boards or $6.50 each. This will be a great addition to my learn to solder board selection for my learn to solder classes. Thank you David johnson-Davies for sharing you projects and knowledge.

Directions for Use

The game does not have an on/off switch. The ATtiny85 just goes into deep sleep unless the buttons are pushed. My battery is still good even after being on the shelf for many months.

To start the game press the center start button. The red and yellow LEDs flash for 5 seconds. During that time choose one player or two player. If you don't choose it goes back to sleep and you have to press the start button again.

The one player game works like the original Simon. The game will choose a color at random then wait for you to push a button. If correct the game adds another random color to the sequence and you have to repeat it. If you choose a wrong button the game gives a fail tone and goes to sleep. If you happen to get up to 32 in the sequence you will hear a winning tune. (I never have!)

In the two player game the first player chooses a button and hands to the second person. The second person repeats the button and adds one to the sequence. Then back to the first person who does the sequence and adds one. Play continues until one person fails.